Versaflex Flat Top Chain Conveyor System

The flexible solution.

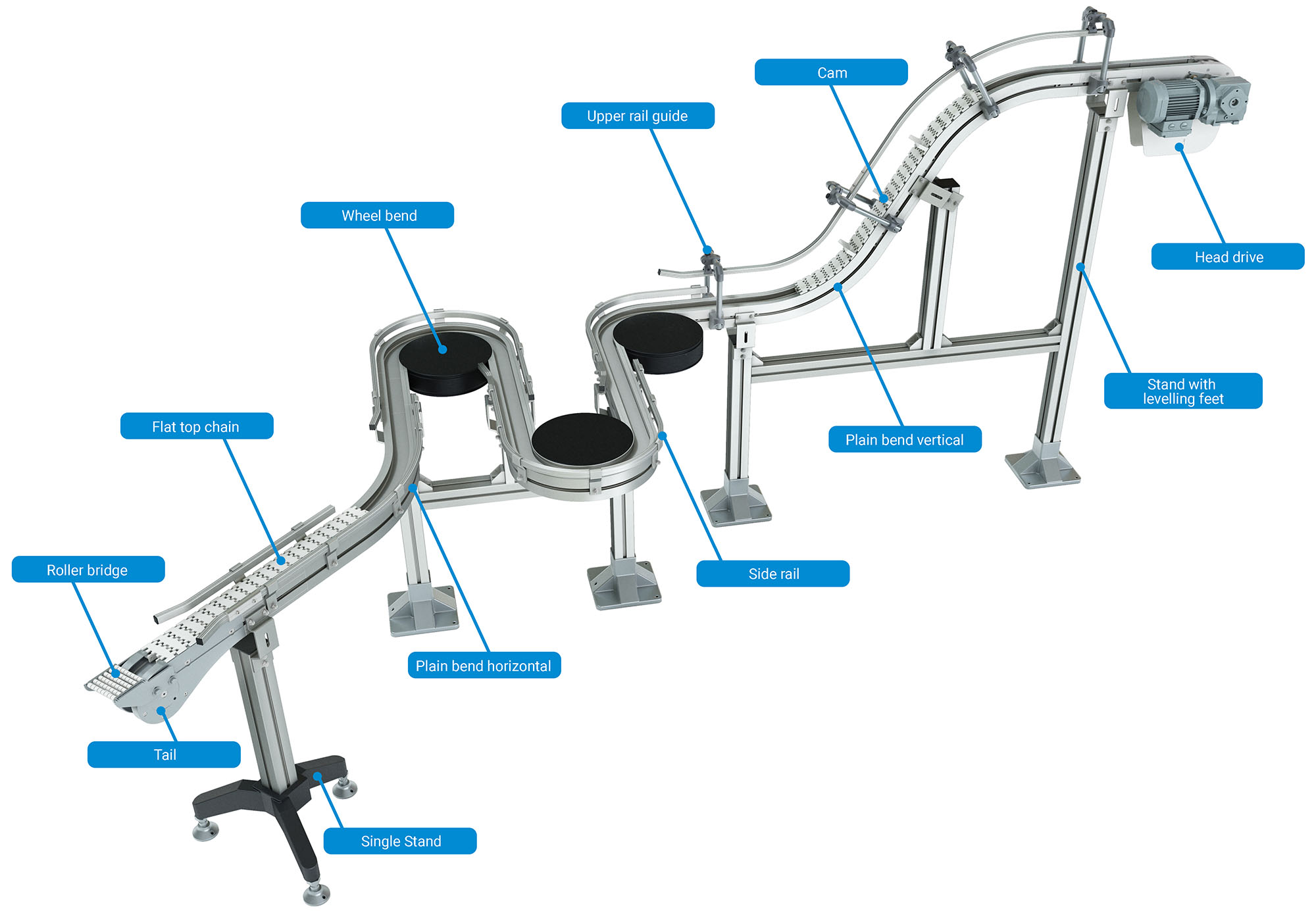

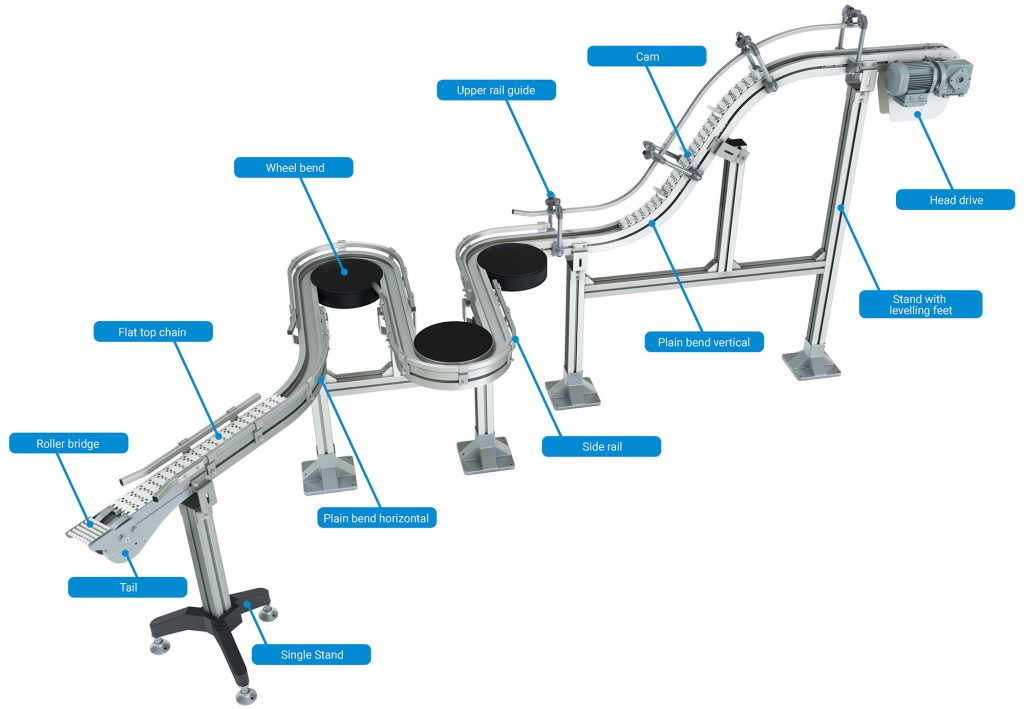

The Versaflex flat top chain conveyor system, fully modular and standardised, is well-suited for intricate track layouts within a three-dimensional environment. Its various chain widths enable swift configuration and trouble-free system design, optionally accommodating workpiece carriers.

The Versaflex flat top chain conveyor system, previously known as the plastic chain conveyor from E-M-M-A GmbH, boasts a modular design. Its standardised modules and components facilitate easy and cost-effective integration into various production processes, allowing for seamless adaptation and expansion. Versaflex is a conveyor system that can evolve alongside your changing requirements.

Furthermore, it seamlessly integrates with existing market-available systems and has proven to be highly effective across various industries. It excels in transporting both primary and secondary-packaged products, particularly in sectors such as food, pharmaceuticals, chemicals, and consumer goods. Additionally, it is well-suited for conveying workpiece carriers in assembly lines, such as those in the automotive industry, and for seamlessly connecting machines in the manufacturing industry.

Advantages of Versaflex:

Cost-effective implementation of intricate track layouts

Effortless and rapid setup and deployment

Applicable across all industries, compatible with current systems

Modular system comprising standardized components

User-friendly with minimal maintenance requirements

Quick adaptability to changing production and environmental conditions

Efficient use of energy and space

Attachments such as accessories and side rails can be easily affixed to the slots on the conveyor frame profile.

Advantages of Versaflex:

The single-track configuration and curve radii beginning at 150 mm enable the mapping of intricate paths in three-dimensional space. The chain operates on wear strips to minimize wear and is designed for operation with a single drive, reaching speeds of up to 50 m/min and standard system lengths of up to 40 m.

Alongside the conveying paths, a variety of supplementary components augment the construction kit, providing flexibility in system design. mk provides drives, bends, cleats, side rails, and stands tailored to the specific task and conveyed goods. Additionally, various function modules are at your disposal, including stoppers for accumulation, buffering, or product separation, as well as switches for diverting products onto different conveying paths.

Versaflex Conveyor Chains

A product can be two or three times the width of the conveying chain, provided the centre of gravity of the transported goods is within the chain width, additional supporting tracks may be required.

| Chain width [mm] | System width [mm] | Product width [mm] | Max. product weight [kg] | Max. total load [kg] | Max. length [m] | Max. speed [m/min.] | ||

|---|---|---|---|---|---|---|---|---|

| Versaflex A06 |  | *63 mm | 65 mm | 15-140 mm | 10 kg | 150 kg | 40 m | 50 m/min. |

| Versaflex A08 |  | *83 mm | 85 mm | 20-200 mm up to 150 mm (P08) | 15 kg 10 kg (P08) | 200 kg | 30 m | 50 m/min. |

| Versaflex A10 |  | *103 mm | 105 mm | 25-300 mm | 20 kg | 200 kg | 30 m | 50 m/min. |

| *Other chain widths are available on request. | ||||||||

Constructed from POM material, the chains come in a diverse range of configurations suitable for nearly all applications. Options include chains with adhesive surfaces for inclines, those with steel coverings for handling sharp-edged parts, and flocked chains for transporting delicate items. Additionally, a variety of cleats are on offer, including rollers of varying dimensions for accumulating products and flexible cleats for implementing clamping conveyors. Moreover, chain links with embedded magnets are available for transporting magnetizable parts.

Versaflex P08 Workpiece Carrier System

For precise product positioning, the A08 system can also transport workpiece carriers. As previously mentioned, the system is 85 mm wide (chain width 83 mm) and is intended for products weighing up to 10 kg per carrier. The carriers, with a standard width of 150 mm, are guided by side rails and precisely positioned in three levels within the locating stations. This ensures that products are securely fixed, buffered, and transported with care, safety, and accuracy.

The workpiece carrier is customisable and can be fitted with unique fixtures. The locating station can be freely placed without requiring adjustments to the side rails. A positional accuracy of ± 0.1 mm is attained by lifting the workpiece carrier off the conveyor chain.