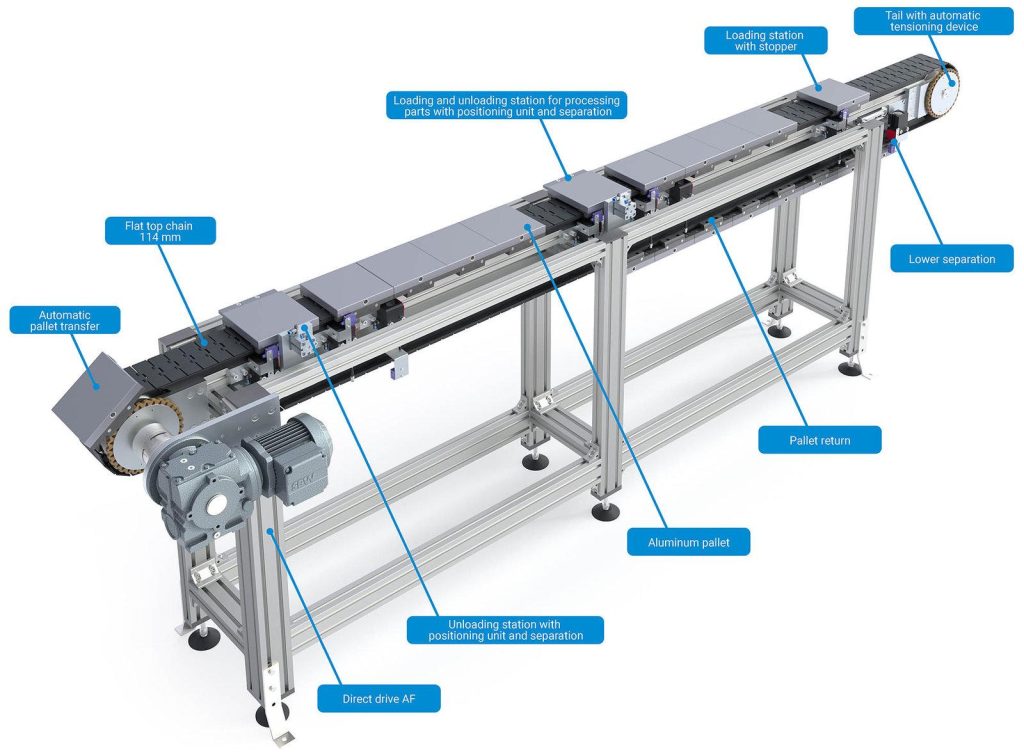

SPU 2040 Accumulation Conveyor

Loading and buffering workpiece carriers in confined spaces

The SPU 2040 is an accumulating pallet recirculation system that offers automated and cost-effective processes for dynamic feeding, buffering, positioning, and separating pallets even in the most restricted spaces. With its robust design and versatile range of options, this system is well-suited for a wide array of automation and material flow applications.

The SPU 2040 facilitates acyclic operation, meaning it operates independently of the infeed cycle, with automatic recirculation of workpiece carriers. Workpieces on these carriers are transported along the upper transport level by the flat top chain. Once a workpiece is removed, empty carriers are safely conveyed around the tail and then returned below the transport level. This process ensures they are ready at the start of the belt for loading with new workpieces, eliminating the necessity for a second conveyor level or intricate control elements in lift-and-lower units. Moreover, there is no need for manual or automatic loading of workpiece carriers onto the belt.

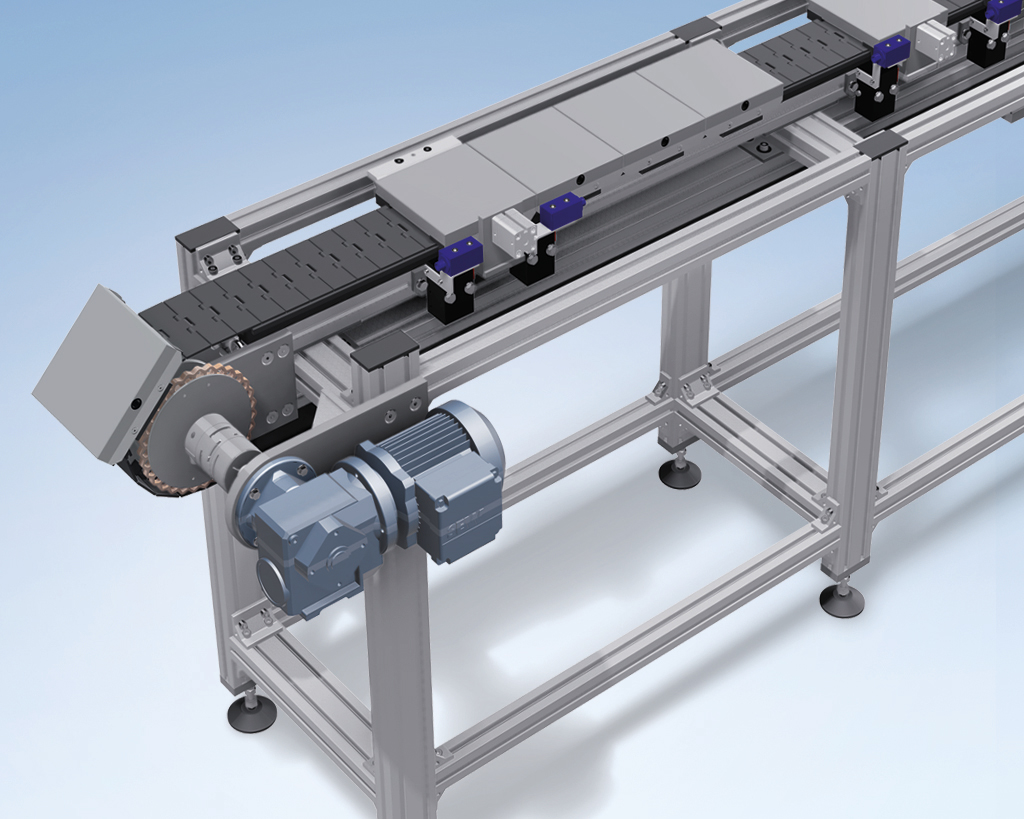

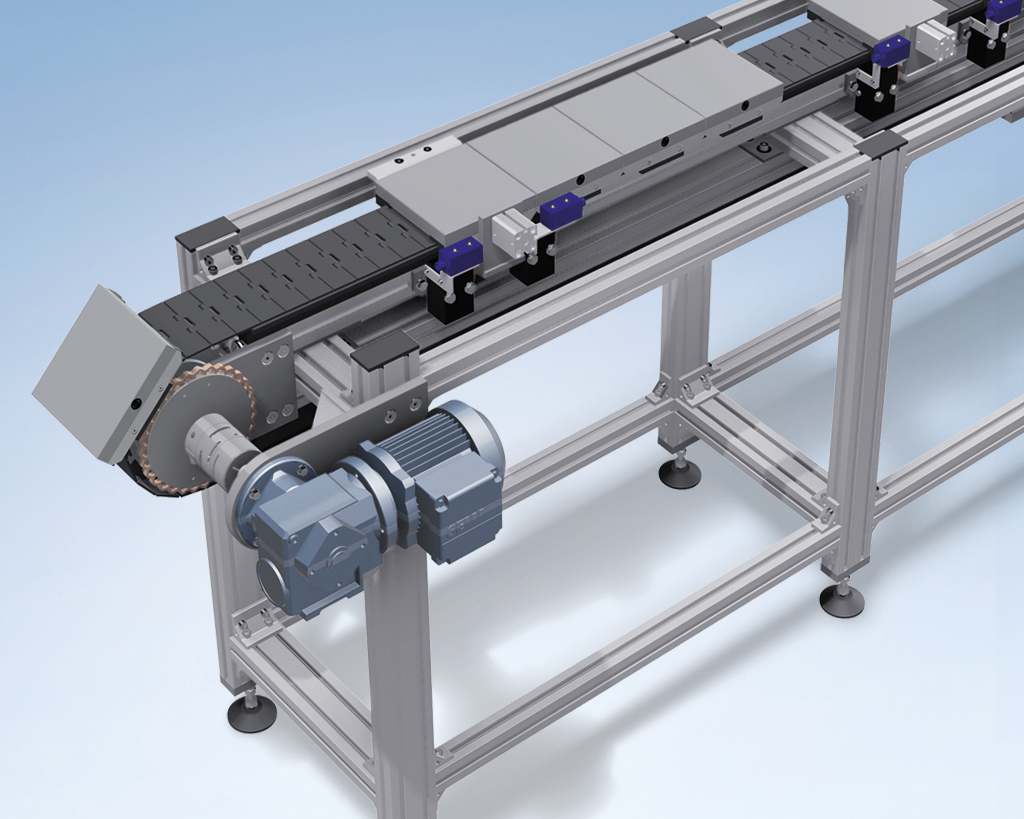

Single-line SPU 2040

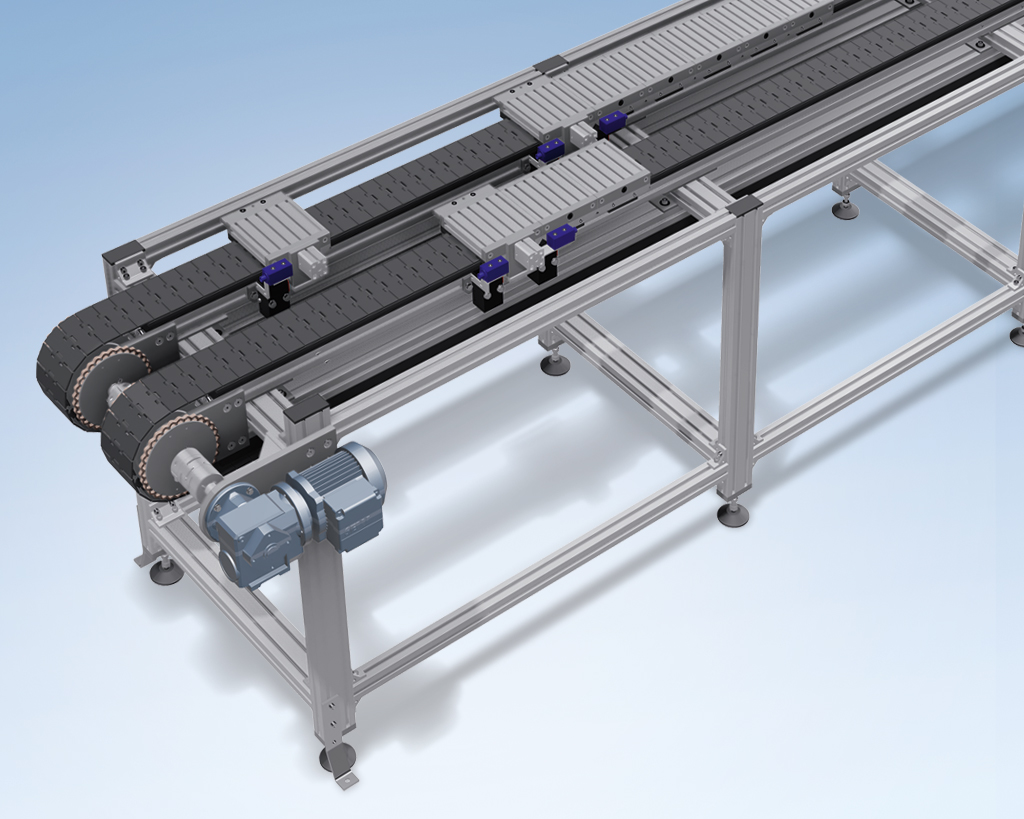

Dual-line SPU 2040

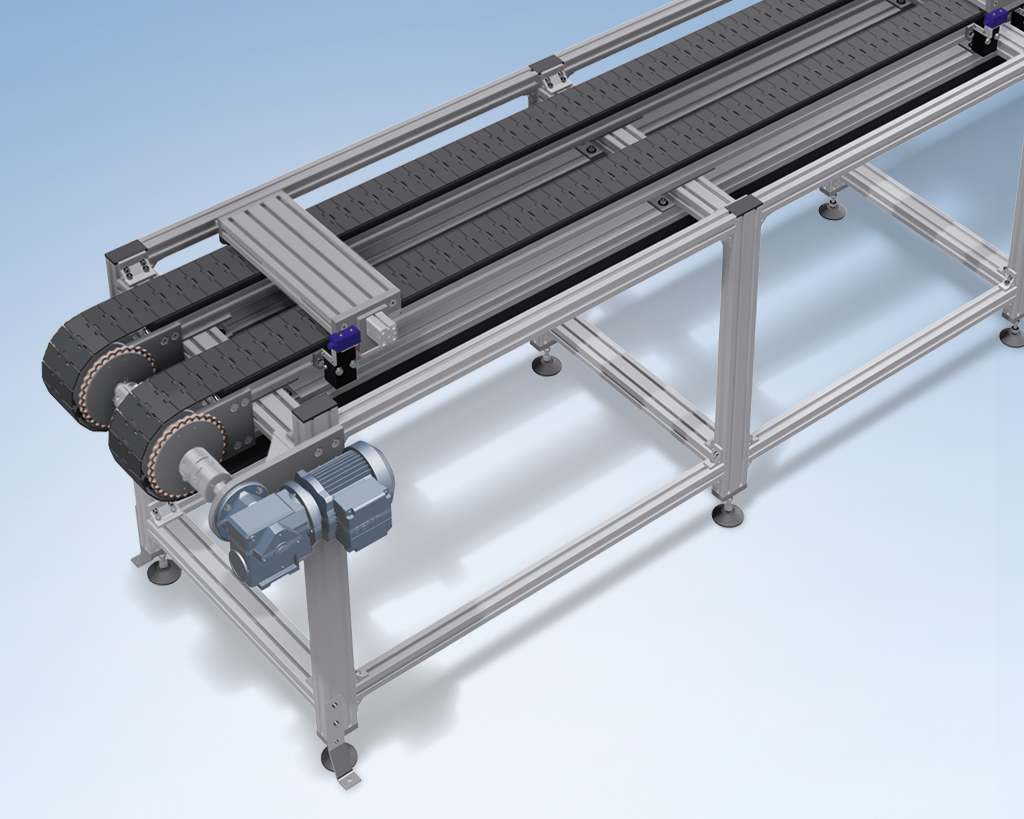

Double-line SPU 2040

Advantages of the SPU 2040:

Economical and space-efficient connection between two machining stations.

Dependable and agile processes for feeding, buffering, positioning, and separating.

Compact structure with a space-efficient recirculation of workpiece carriers beneath the transport level.

Buffering capability to accommodate varying cycle times in the production line.

Constructed using reliable mk modules and a range of workpiece carriers for exceptional flexibility.

Transfer lines available in lengths ranging from 2 to 10 meters.

Speed options ranging from 4 to 15 meters per minute.

Requires minimal maintenance and exhibits low wear.

Overview of the SPU 2040

Pallets:

- Support plates made from aluminium plates or Series 40 aluminium profiles

- Lateral positioning slot and positioning socket ensure high positioning precision

- Pallet width for single and multi-line systems 160 or 236 mm. In double-line systems depending on the width of the conveyor. The standard length of a pallet is 160 mm.

- The max. permissible unladen weight depends on the type of system and the height of the workpiece holder

Lane construction:

Wear-resistant carbon steel is used for the flat top chain.

There are two available chain widths:

- 114 mm for single, dual, and double lines

- 190 mm for single lines

Tail with automatic tensioning device:

- Secure transfer is ensured by Vulkolan cleat pads.

- 40mm tensioning distance.

- The optimal tensioning pressure is set at 6 bar.

Drive options:

There are two available drive types on either the left or right side of the conveyor line:

- AF head drive direct, featuring a flange-mounted hollow shaft motor.

- AC head drive indirect, equipped with a gear motor with a shaft journal.

- Conveyor speeds range between 4 to 15 m/min, depending on the required pallet cycle time.

- Secure pallet transfer is guaranteed by Vulkolan cleat pads.

Positioning unit with separation:

- Electrical cylinder detection is available optionally, with inductive detection as an option.

- The stopper cylinder can detect either one or both switch settings.

- The lifting force is determined by the sum of pallet, fixture, product, and counter pressure, reaching a maximum of 140 N (at 4 bar) and 210 N (at 6 bar). Higher lifting force options are available based on customer requirements.

- Precise positioning with an accuracy of ±0.2 mm is achieved.

Safety guard with pendulum flap:

The safety guard at the tails is designed to minimize the risk of injury to the operator. A pendulum flap when touched is activated, halting the entire system. Upon request, a cover between the flat top chain and the frame can be provided. Additionally, a safety guard without a pendulum flap in profile design or as a sheet metal hood is available as an optional feature.