Chain Conveyors

Efficiently Carry Bulky Loads, Even in Continuous Operations

Chain conveyor systems excel in the repetitive transportation of workpieces or pallets. They come with various drive options and are frequently employed to create intricate interconnection solutions.

Commonly, they find application in moving workpiece carriers with substantial weights and maintaining high speeds within a dual or multiple line setup.

For tasks requiring high speeds or precise positioning, low-maintenance and quiet timing belt conveyors are the preferred choice.

Technical specifications:

Width Range: 200–2000 mm

Length Range: 500–10,000 mm

Maximum Load Capacity: Generally up to 1000 kg

Operational Speed: Up to 30 m/min Configuration Options: Single line or multiple line

Additional values can be provided upon request

Diverse chain variants, coupled with robust and durable wear strips, guarantee dependable, extended operational performance tailored to your specific application.

mk Chain Conveyor Overview:

| Conveyor name | Conveyor- | Conveyor- | Total load | Speed | ø of tails | Reverse | Accum. | Cycling |

| width [mm] | length [mm] | up to [kg] | up to [m/min] | [mm] | operation | operation | operation | |

| Chain conveyor KTF-P 2010 | 200-2000 | 500-10000 | 500 | 57 | ca. 89 | X | X | X |

| Accumulating chain conveyor SRF-P 2010 | 200-2000 | 730-10000 | 500 | 30 | ca. 89 | X | X | X |

| Accumulating chain conveyor SRF-P 2012 | 200-2000 | 1000-10000 | 1000 | 30 | ca. 89 | X | X | X |

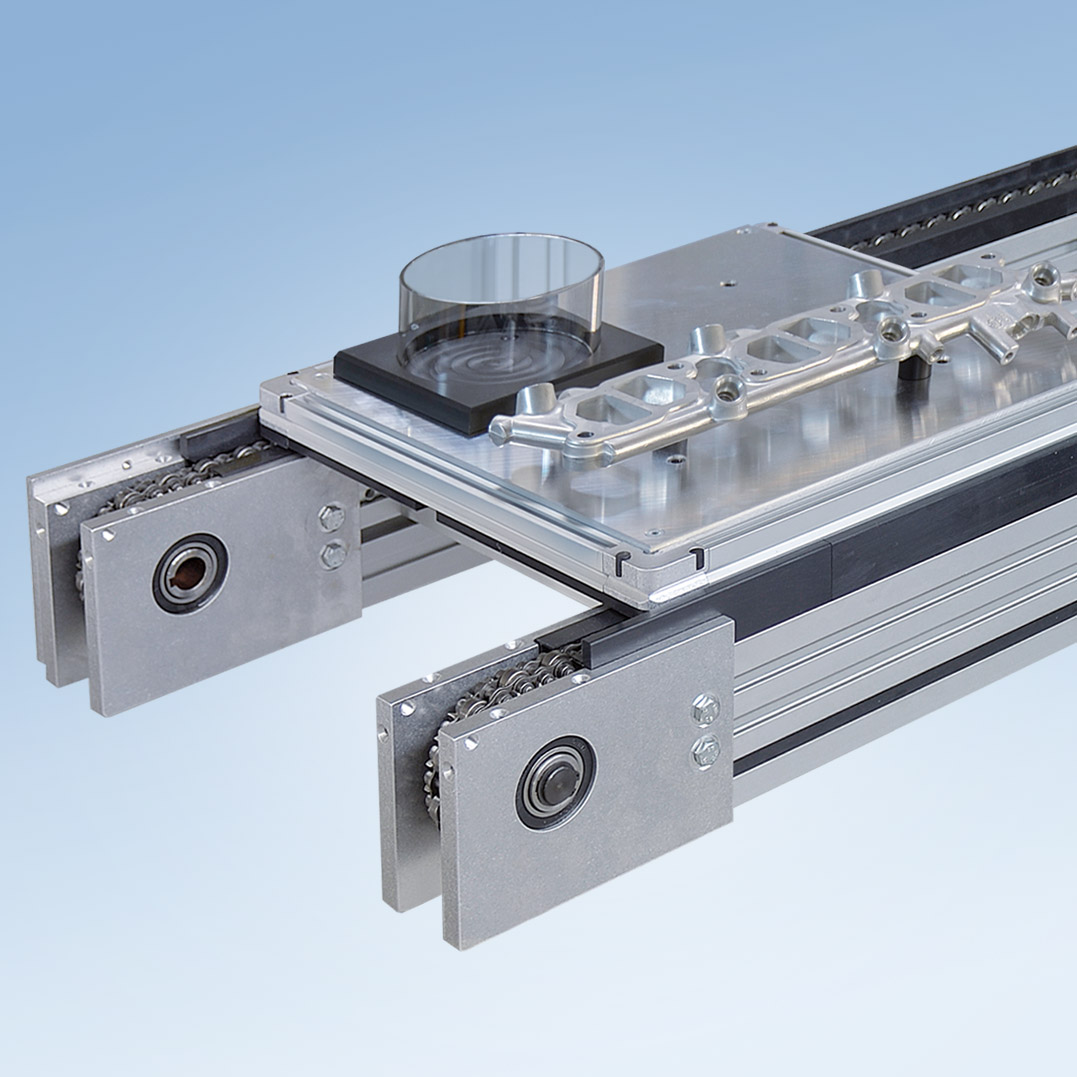

KTF-P 2010 Chain Conveyor

A chain conveyor system featuring various drive options designed to transport workpiece carriers efficiently, even under heavy loads.

Click on image to enlarge

Technical specifications

| Type of goods | Boxes, crates, pallets, workpiece carriers |

| Type of ways | Straight & incline up to 20° |

| Length | individual 500-10000 mm |

| Width | 200-2000 mm |

| Speed | up to 30 m/min |

| Maximum load | up to 500 kg |

| Chain | 1/2“ single or duplex |

| Drive versions | AA, AC, AF, AS, C, BF |

| Belt body profile | mk 2010 |

Characteristics of the KTF-P 2010

Foundation for building transfer systems designed for higher loads

Well-suited as a dual or multiple line system for transporting workpiece carriers

Extensive variety of drive options

Low-maintenance and robust for use in cyclic operations

SRF-P 2010 Accumulating Roller Chain Conveyor

An accumulating roller chain conveyor designed to interlink workstations and buffer workpiece carriers efficiently under heavy loads.

Click on image to enlarge

Technical specifications

| Type of goods | Boxes, crates, pallets, workpiece carriers |

| Type of ways | Straight & incline up to 20° |

| Length | individual 500-10000 mm |

| Width | 200-2000 mm |

| Speed | up to 30 m/min |

| Maximum load | up to 500 kg |

| Chain | Accumulating roller chain 1/2“ with plastic- or steel rollers |

| Drive versions | AA, AC, AF, AS, BC, BF |

| Belt body profile | mk 2010 |

Characteristics of the SRF-P 2010

Foundation for constructing transfer lines with accumulated operation

Well-suited for low-maintenance and durable use in accumulated and cyclic operations

Designed for interlinking and buffering between workstations and transporting workpiece carriers

Offers a wide selection of drives

SRF-P 2012 Accumulating Roller Chain Conveyor

An accumulating roller chain conveyor designed to interlink workstations and offer buffering between them, specifically within the heavy load range.

Click on image to enlarge

Technical specifications

| Type of goods | Boxes, crates, pallets, workpiece carriers |

| Type of ways | Straight & incline up to 20° |

| Length | individual 1000-10000 mm |

| Width | 200-2000 mm |

| Speed | up to 30 m/min |

| Maximum load | up to 1000 kg |

| Chain | Accumulating roller chain 3/4“ with plastic- or steel rollers |

| Drive versions | AA, AC, AS, BC, BF |

| Belt body profile | mk 2012 |

Characteristics of the SRF-P 2012

Foundation for building transfer lines with accumulated operation

Well-suited for low-maintenance and durable use in accumulated and cyclic operations

Designed for interlinking and buffering between workstations and transporting workpiece carriers

Offers a wide selection of drives