Find out here how a mechanical engineering company utilised the mk conveyor range to achieve a customised solution for their material flow requirements. The machine manufacturer builds dosing systems for foaming a wide variety of products with sealing, casting and adhesive compounds. They required a partner that could provide the conveyor technology and the corresponding know-how for its material flow.

A tailored individual conveyor line was required by the customer. Large plastic lids in different shapes and dimensions needed to be transported, cleaned automatically and foamed at a dosing station. To ensure that the cleaning and dosing systems could be aligned properly, the lids needed to be positioned with a repeat accuracy of +- 1 mm. The changeover time that needed to be observed was four seconds.

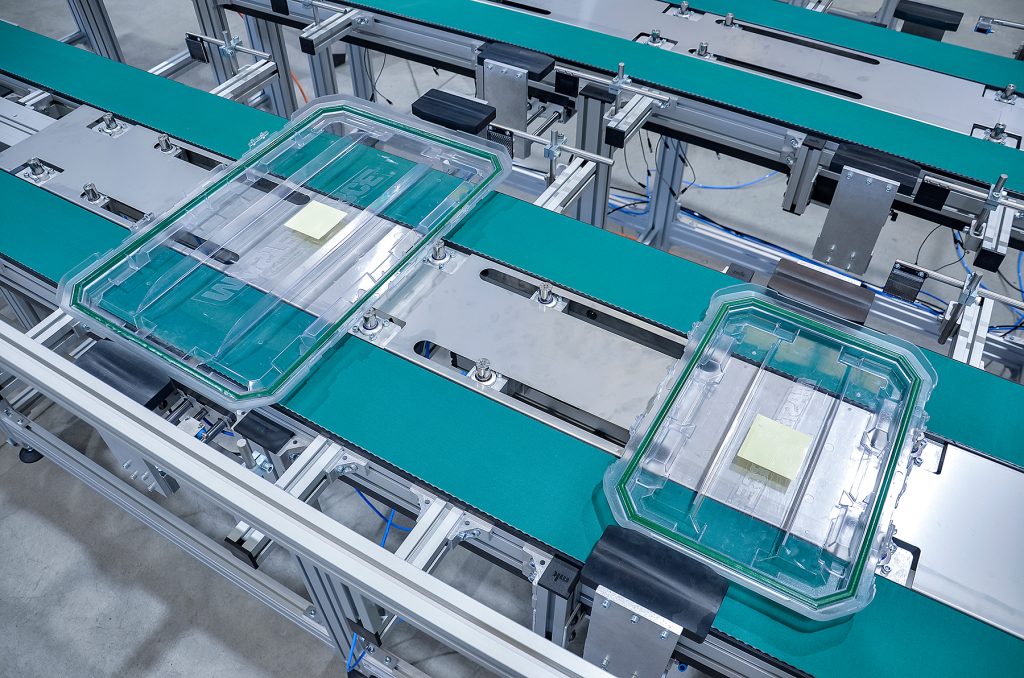

The solution provided required two parallel conveyor lines for this application. Each line comprised of two belt conveyors at the infeed and outfeed of the line. In between there are timing belt conveyors that serve as a centring station. The cleaning and dosing systems are attached to an overhead gantry above the conveyor lines by the customer.

The transitions between the conveyors were equipped with rolling knife edges for problem free transfer. Guides were also attached to the belt conveyor as stops to ensure that the lids are placed and removed in the correct position.

The lids move against a pneumatic stop for both process steps – cleaning and application – while a second pneumatic stop clamps the lid from behind. The square lids are also pneumatically clamped from the sides. This allows the significantly different formats to be positioned securely. The lines are designed so that the varying configurations can be processed without retooling and without changing parts.

The mk belt conveyor range is extensive and incorporates a wealth of standard modules and accessories that can be adapted to meet a customer’s bespoke requirements. It has a large number of options for lightweight and medium weight products and is both sturdy, and versatile. There is even a free online configurator available for customers to use to quickly and easily create their own custom belt conveyors. QuickDesigner provides a no obligation quote alongside a CAD model for reference.

The mk timing belt conveyor was the other key product used in this application. This is a conveyor system with a timing belt for cycled transport of piece goods. Its fast, precise and flexible nature made it the perfect choice to satisfy the needs of this mechanical engineering company.

It is this knowledge and adaptability that has led to a long-term relationship with this customer and has given them the confidence to put their trust in mk conveyors to provide the solution.

As the only UK and Ireland distributor of the mk conveyors please get in touch to see how we can help you achieve your required solution. We have lots of information on the extensive mk conveyor range and you can also access QuickDesigner, our free online belt conveyor configurator.