Guarding

Machine Guarding and Protective Fences for Increased Occupational Safety

When humans and machinery collaborate, safety and protection take precedence. To ensure occupational safety, machine enclosures, cabins, and safety barriers are employed. mk provides custom-designed safety solutions using modular aluminium profile construction, tailored to specific needs and highly adaptable.

Select from an extensive assortment of panels, doors, and windows, with the option for electrical security if needed. Integrating pneumatically, hydraulically, or electrically operated door elements into your machine control system is effortlessly achieved. All safety enclosures are meticulously designed and manufactured in compliance with the prevailing safety regulations in your region, ensuring the utmost security for both you and your staff.

Advantages of mk Guarding

Utilizes a modular approach built upon our aluminium profile system.

Marries an appealing design with robust and functional qualities.

Adopts screw connections, allowing for easy expansion and modifications.

Offers a choice of assembly levels, from individual components to fully assembled enclosures.

3D products available to design your guarding quickly and easily.

What is the rationale for utilising the mk Profile System?

In addition to providing you with the option to completely customise your guarding, mk also offers the following standard variants.

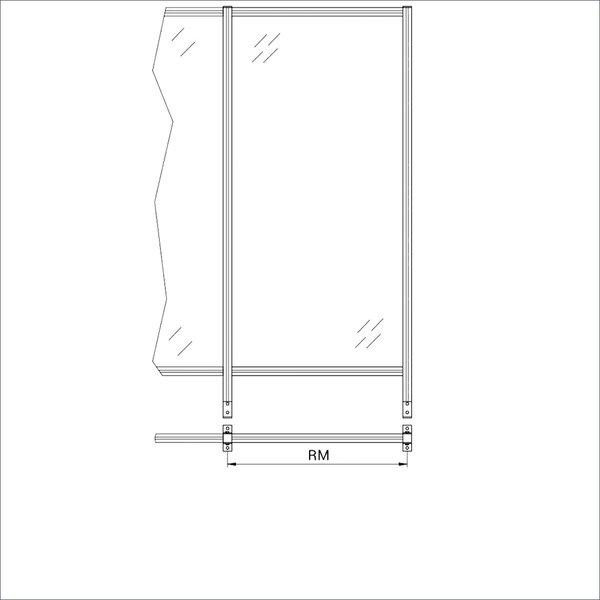

ECO Solution

Because it requires less material, the ECO solution is the most cost-effective alternative, but it requires significantly more installation work.

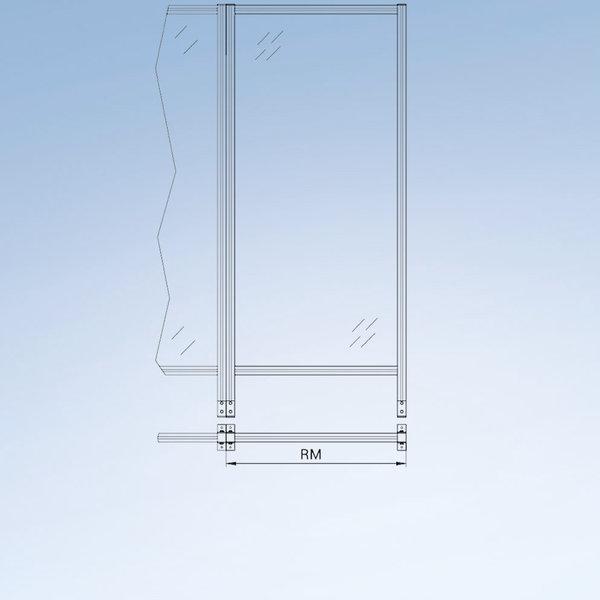

Partition Method

In the partition method, the posts and the panelling material form a single unit. The units are placed next to each other, connected with plates or adjustable angles and anchored to the floor.

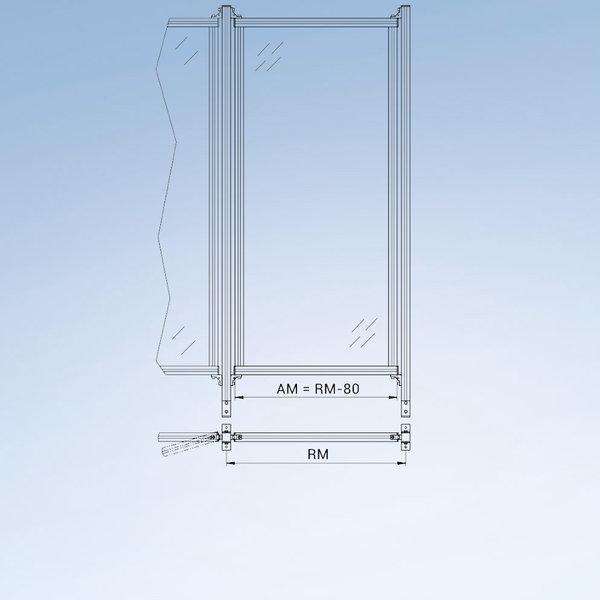

Post-Panel Method

In the post-panel solution, the separate panel frames are not connected to each other but rather attached using angles to posts that are anchored to the floor. This option demands additional installation but comes with the advantage of quicker and easier access points for maintenance. The use of angles for mounting the panels permits installation at different angular orientations.