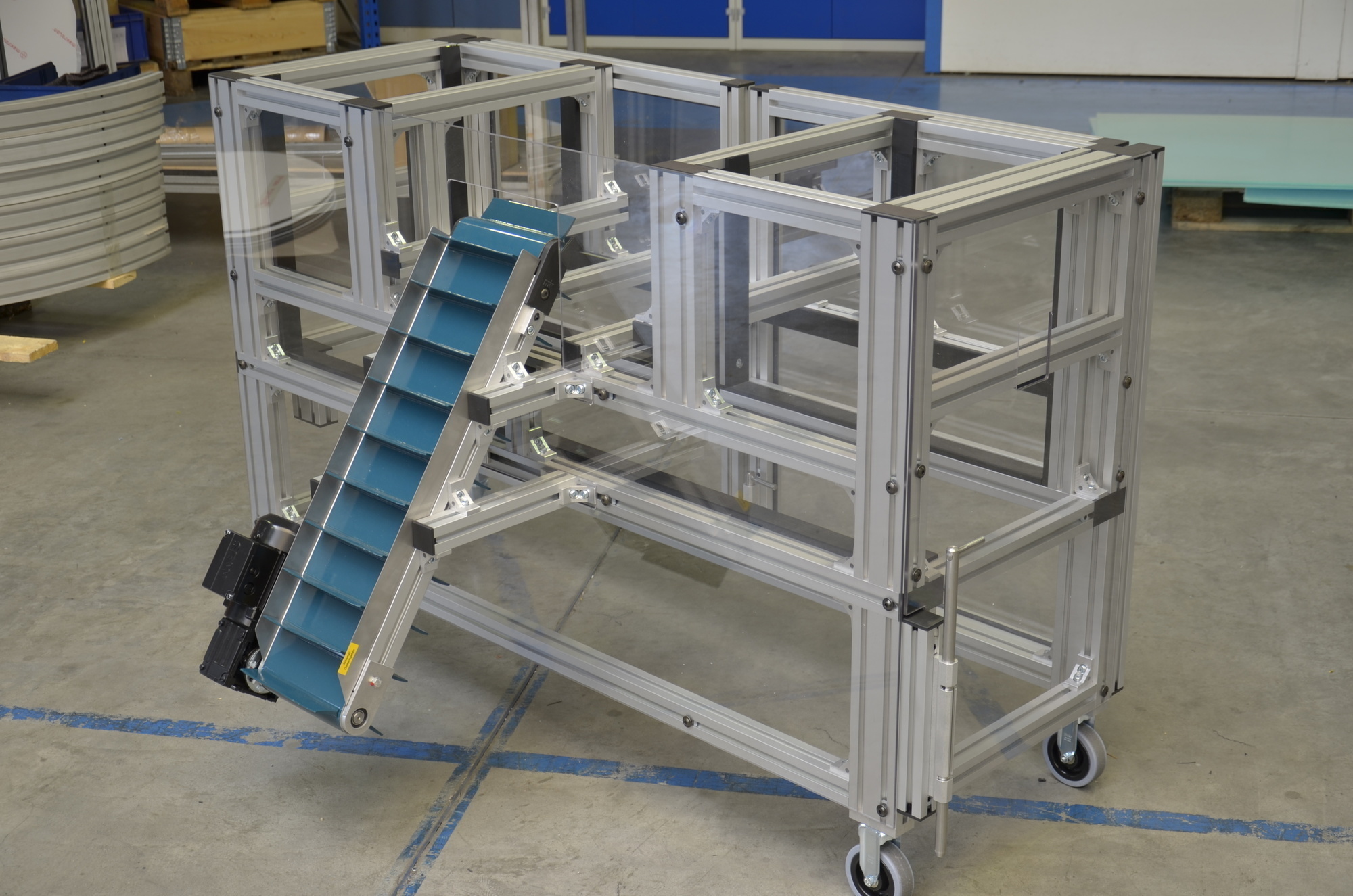

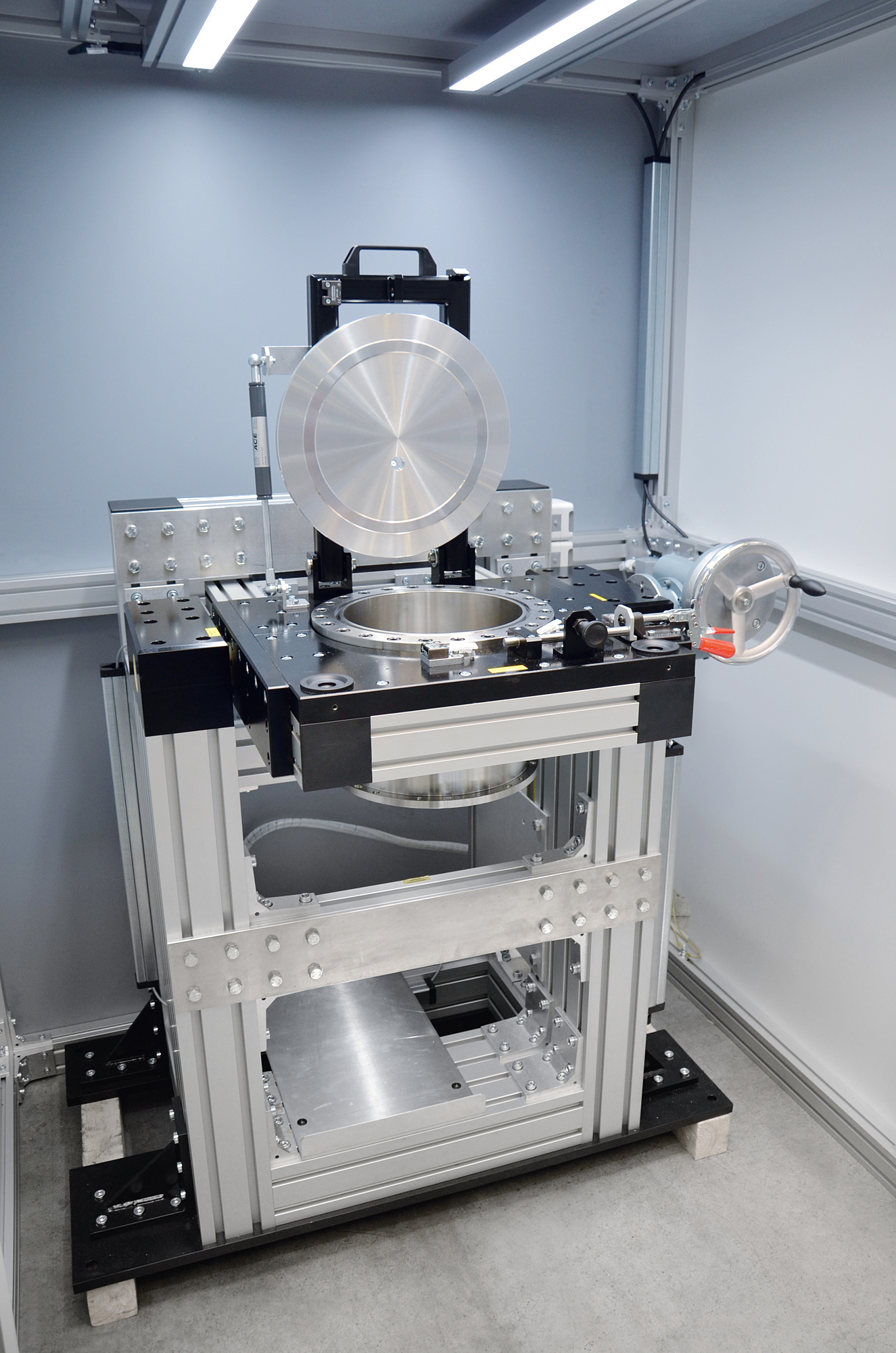

Using T-Slot extruded aluminium profiles for building machine frames offers numerous advantages over traditional steel welding methods. Here’s an in-depth look at why this method stands out:

Advantages of T-Slot Extruded Aluminium Profiles

1. Eliminates Welding and Surface Preparation

- No Welding Required: T-Slot extrusions can be connected using various fasteners and connectors, eliminating the need for welding.

- Anodized Finish: The profiles come pre-anodized, providing a superior and durable surface finish compared to traditional paint jobs. This also eliminates the need for messy and toxic painting processes.

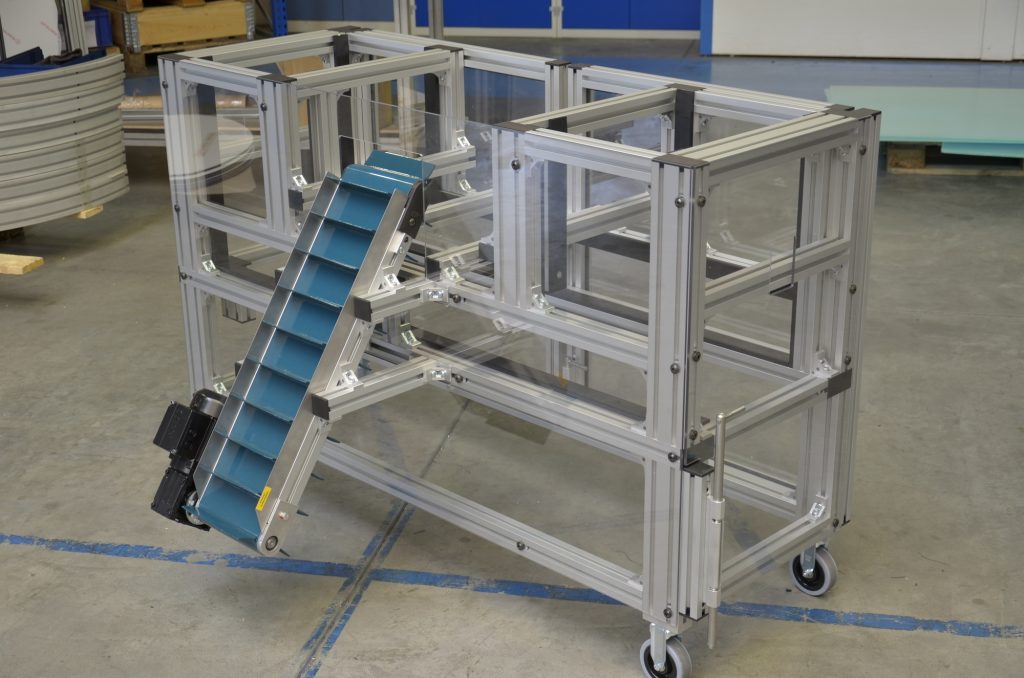

2. Ease of Use and Flexibility

- Easy Cutting and Assembly: Aluminium profiles are much easier to cut and handle compared to steel. The assembly process is straightforward, requiring simple tools.

- Modular Design: The T-Slot system allows for easy modifications and adjustments. Frames can be dismantled and reassembled if design changes are needed, providing flexibility during the build process.

3. Precision and Reduced Rework

- No Distortion: Unlike welding, which can cause distortion due to heat, T-Slot assemblies maintain their precision and alignment, reducing the need for rework.

- Consistent Tolerances: The precision machining of T-Slot extrusions ensures that all components fit together accurately, maintaining consistent tolerances throughout the build.

4. Cost and Time Efficiency

- Reduced Labour Costs: By eliminating welding, grinding, and painting, labour costs are significantly reduced.

- Quicker Turnaround: Preparation and assembly times are reduced, leading to faster project completion.

5. Safety and Environmental Benefits

- No Hazardous Processes: The absence of welding, grinding, and painting reduces the exposure to hazardous fumes and materials, creating a safer working environment.

- Environmentally Friendly: The anodized aluminium finish is more environmentally friendly compared to traditional painting processes that involve solvents and chemicals.

6. Durability and Strength

- High Strength-to-Weight Ratio: Aluminium profiles provide a strong and lightweight solution for machine frames, ensuring durability and ease of handling.

- Corrosion Resistance: The anodized surface of the aluminium provides excellent corrosion resistance, ensuring the longevity of the frame.

Conclusion

Switching to T-Slot extruded aluminium profiles for your machine frames can greatly enhance the efficiency, precision, and flexibility of your build process. The elimination of welding and painting not only reduces costs and time but also improves safety and environmental impact. With the added benefit of modularity and ease of assembly, T-Slot extrusions offer a superior alternative for high-quality machine frame construction.

Whether you are a seasoned builder of complicated machinery or a complete novice, building a frame with T-Slot Aluminium extrusions is easy.

As the only UK & Ireland distributor of the mk Technology Group aluminium profile range, let us help you create your ideal machine frame. The range includes:

- 40 x 40 profile – ideal for lightweight machine frames

- 50 x 50 profile – for heavy-duty machine frames with high static loads

- 60 x 60 profile – the most robust profiles which are the perfect choice for machine frames required to handle the heaviest loads, multi-axis gantries and lifts.

We can assist with your design and help you to select the best connection method. We can provide a fully assembled solution or a kit of parts if you prefer to assemble yourself.

Contact us now and let us help you realise your manufacturing solution!