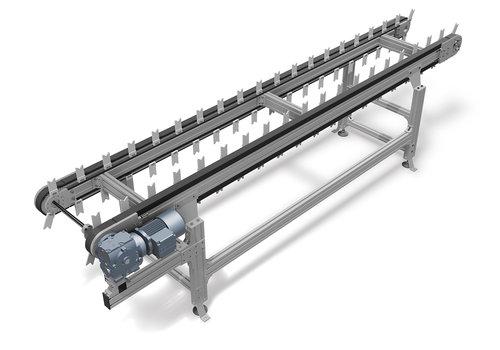

TKU 2040 Indexing Chain Conveyor

Cycled interlinking of Machines and Machining Centres

The TKU 2040 chain conveyor system is particularly suitable for the systematic, predetermined, and position-oriented feeding and retrieval of elongated cylindrical components. The timing of the system can be customised to adhere to a specific cycle. It finds applications in various industries, including machine tools, plastics, automotive, and more.

Built upon the mk profile system, the TKU 2040 is a modular, compact, flexible, and highly robust solution. It features a timing chain conveyor with two roller chains, enabling a maximum load capacity of 700 kg. The conveyor frame comprises two profile sections with sliding assemblies for both the chain and the fixtures for workpieces. This system is offered in configurations with a fixed width or an adjustable width. The width adjustment mechanism facilitates the handling of workpieces of different sizes.

TKU 2040 with fixed width

TKU 2040 with adjustable width

To meet particular specifications, workpiece fixtures made from either polyoxymethylene (POM) or brass prisms can be employed, providing an ideal solution for securing cylindrical workpieces. Alternatively, profile workpiece carriers are available, allowing customisation with customer-supplied workpiece fixtures.

TKU 2040 Highlights:

Economically links machining stations

Robust system supports a load capacity of up to 700 kg

Handles loads of up to 6/10 kg (prism) and up to 20 kg (profile workpiece carrier) per workpiece

Compact design for space efficiency

Flexible modular construction

Adjustable variant offer widths ranging from 195 mm to 1500 mm

Strong construction minimises maintenance and wear

Conveyor speeds up to 18 m/min

Achieves a repeatability of +- 1 mm

Summary of the Modules

TKU 2040 – Workpiece Prisms

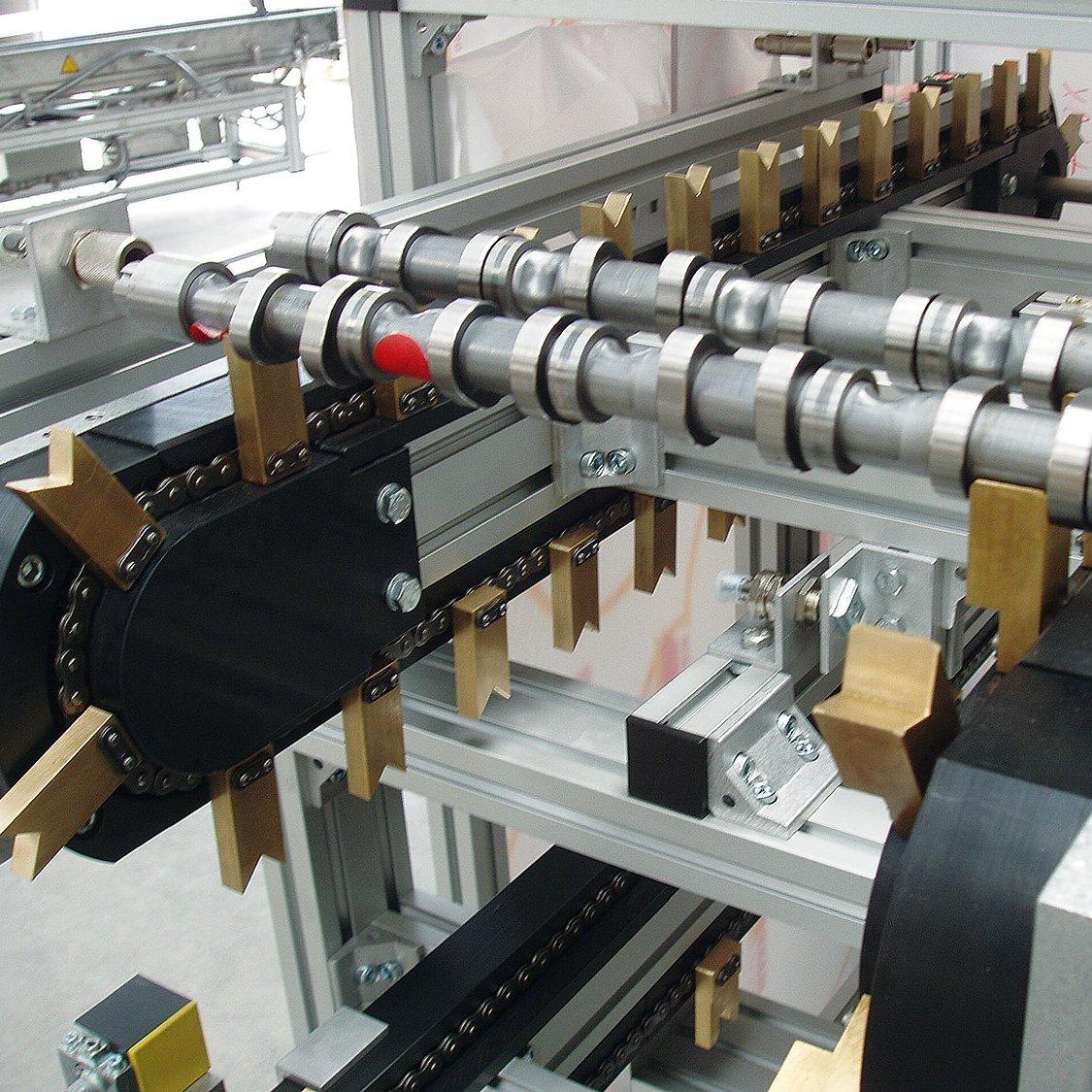

Prism-shaped fixtures are well-suited for the transportation of cylindrical workpieces. POM prisms are specifically crafted for carrying workpieces weighing up to 6 kg each, ensuring damage-free transport. Brass prisms, known for their robustness and heat resistance, can accommodate workpieces of up to 10 kg each.

TKU 2040 – Workpiece Carriers

Workpiece carriers constructed from Series 40 profiles featuring 10 mm slots can be fitted with customer-supplied custom workpiece fixtures. Their width is adjustable within system limits and can bear loads of up to 20 kg. However, it’s important to note that the profile workpiece carrier is not compatible with the adjustable variant.

TKU 2040 – Conveyor Frame

The conveyor frame comprises two profile sections housing gliding assemblies for the chain and the attached workpiece fixtures. Frames with a fixed width feature perpendicular traverses, providing inherent stability and enabling integration into a lighter stand system. For frames with adjustable widths, a specialised width adjustment mechanism is employed, securely fixed onto a support frame.

TKU 2040 – Conveyor Width Adjusting Unit

Adjustable models utilise linear adjusting units to modify the conveyor width, enabling the TKU 2040 to accommodate workpieces of varying sizes. The adjusting unit is provided with either a handwheel or clamping lever, along with a width scale for precision. The width adjustment range is contingent upon the system’s specified limits.

TKU 2040 – Drive Arrangement

The drive system employs a direct drive, known for its compactness, minimal backlash, and low maintenance requirements. This type of drive is highly effective for fixed-cycle operation, as the motor is directly connected to the application. In the case of an adjustable width, the drive features a specialised shaft with a ball bushing, facilitating easy width adjustments.

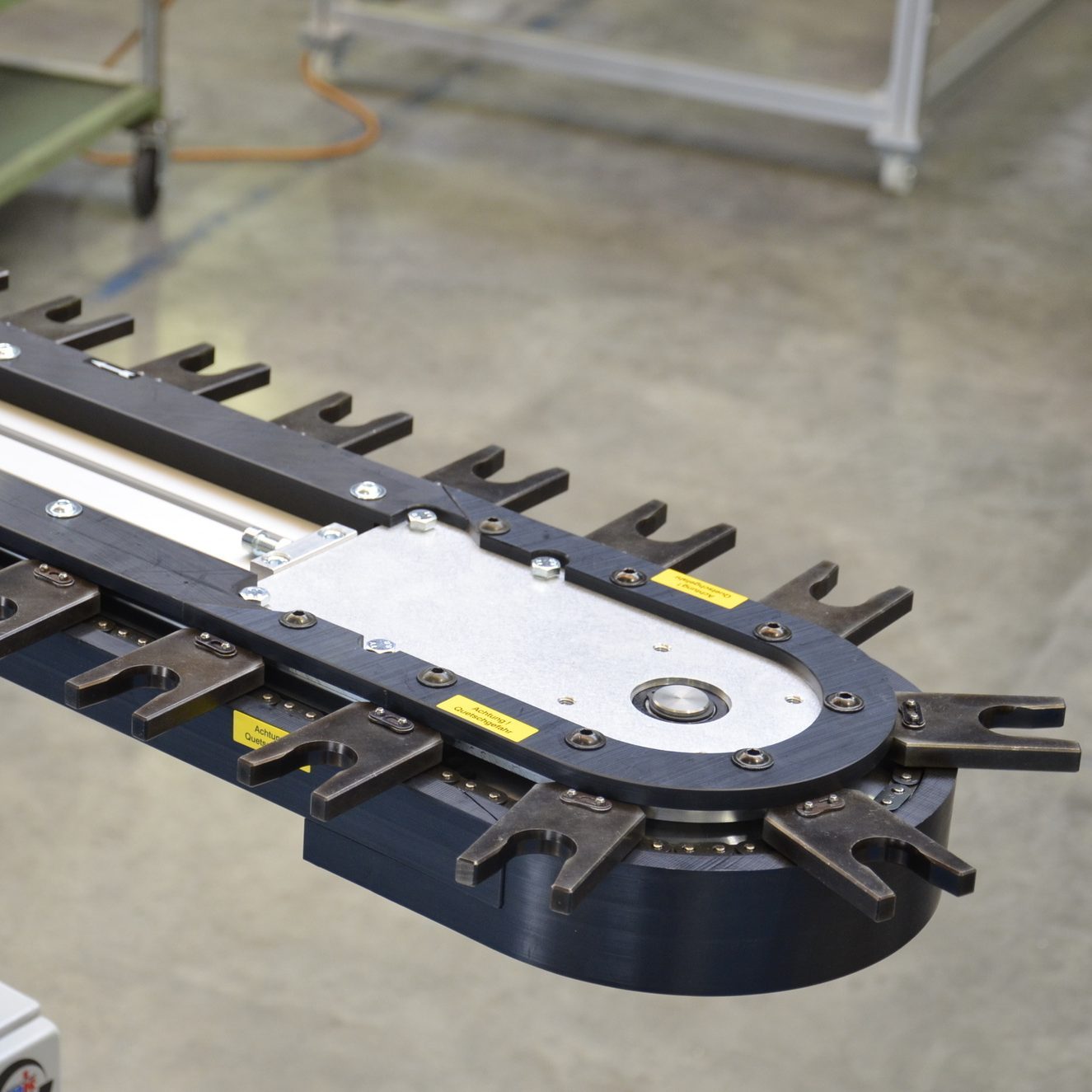

TKU 2040 – Tail Assembly

The tail section incorporates sprockets that effectively drive the transport chain. Tensioning units within the tails allow for convenient adjustment of chain tension as needed.

TKU 2040 – Protective Device Guard

The safety guard serves to prevent access to the device during operation, minimising the risk of injury. The rotary lock activates when moved, bringing the entire system to a halt. It needs to be tailored to the specific contours of the product to ensure that the product itself does not inadvertently trigger the lock.

TKU 2040 – Base Frame

The base frame guarantees system stability and security, offering the flexibility to be ordered in different working heights. Additionally, the frame is customisable with optional panelling, available in either sheet metal or polycarbonate. For added convenience, a mobile version with casters is also an option.

TKU 2040 Application Examples

TKU 2040 for transporting camshafts

Customer-specific TKU 2040 with 20° inclination and transport of workpieces through a cleansing bath