Transfer System Case Studies

Equipment designed for rapid Coronavirus tests with ESD compliance

A medical test manufacturer is constructing a machine for the efficient production of rapid coronavirus antibody tests, capable of producing 40 tests per minute. To meet this demand, the customer necessitates a pallet circulation system for the fully automated assembly of tests by robots. After this initial automated process, the completed products undergo semi-automatic processing on an additional circulation system and are then manually packed by workers. Due to the utilisation of sensitive electronic components in the tests, the entire system will be situated within an Electrostatic Discharge (ESD) protection zone. The ESD protection concept is meticulously designed to prevent potential differences. The production environment is a dry room, maintaining a maximum humidity level of 10%. The machine operates in three shifts to meet production demands.

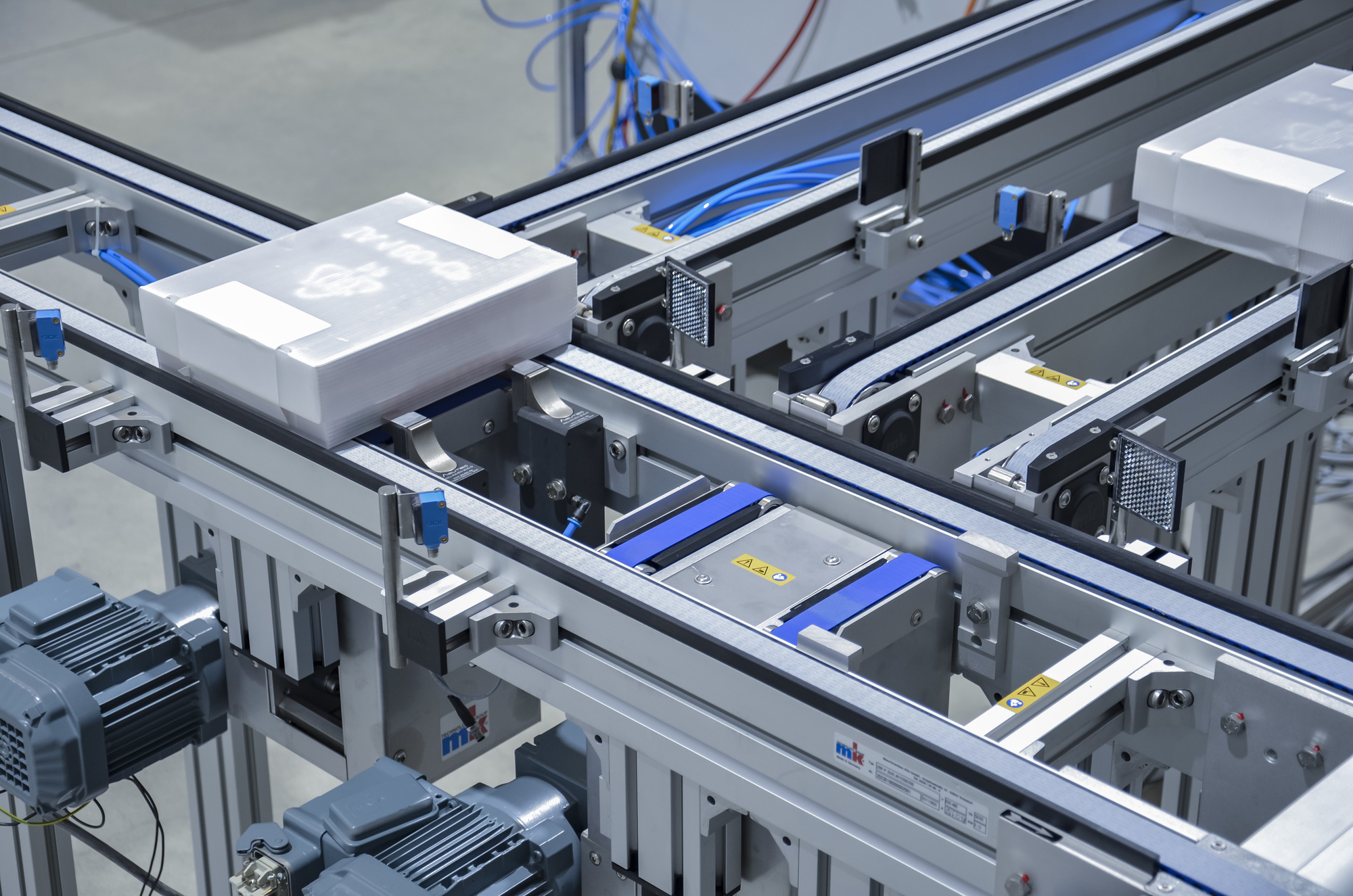

The Versamove plus pallet transfer system emerged as the ideal solution for the specified task. The circulation system was established using timing belt conveyors, featuring antistatic wear strips and timing belts. Careful material selection and design considerations for the ground terminals ensure the prevention of potential differences, meeting the required Electrostatic Discharge (ESD) protection standards. The wear strips and timing belts are also characterised by low wear, resulting in minimal particle emission. The pallet transfer system is versatile, capable of stopping, storing, positioning, and separating. The positioning units enable precise pallet positioning at robot processing stations in the X, Y, and Z directions with an accuracy of 0.1 mm.

Click on image to enlarge

Pallet transfer system for just-in-sequence production

The quality control department of an automotive supplier requires two testing lines. One line is designated for testing the electrical components of the product, while the other is dedicated to performing a tensile test on the product to verify the quality of a locking mechanism. The products are to be checked in a just-in-sequence manner, adhering to a fixed order.

The solution was a Versamove plus transfer system operating on two levels with lifts. The empty pallets are lifted from the lower return level to the upper level using the lift. The products to be tested are attached to the pallets. To test the electrical components of the product, they are electrically connected to the pallet. The products are securely fixed to the pallet on a second, parallel line. A tensile test is then carried out to check a locking mechanism on the product. At the end of the lines, the products are removed from the pallets. The pallets are transported to the lower level with the lift and from there returned to the beginning of the line.

To facilitate the clear identification of products within their designated sequence, RFID chips are incorporated into the pallets, each of which is engraved with a unique number. Upon reaching the start of the line after the lift, the RFID chips are tagged with the corresponding sequence number. Workers are presented with sequence numbers alongside their associated pallet numbers on a monitor, aiding them in correctly processing the products on the assigned pallets.

Before the descent on the lift at the end of the line, the RFID tag is erased, ensuring that blank pallets are conveyed on the return line. This feature enables the insertion of a pallet onto the return line following a repair without any risk of sequence mix-up.

Click on image to enlarge

Assembly and buffering stations for gate valve manufacture

The customer requires a pallet transfer system for the production of gate valves for water pipes, on which the valves can be assembled and buffered. The system then needs to transport the valves to the customer’s dipping station where they are leak tested. Three valves are processed on each pallet, making a total weight of up to 250 kg per pallet. The pallets have to be stopped at the assembly stations. The conveying path needs to be at an ergonomic working height and be secured in accordance with accident prevention regulations (UVV).

The transfer system was assembled using a combination of chain conveyors and accumulating roller chain conveyors. The chosen profile series was tailored to accommodate the specific loads in the processing workflow. The conveyors create a closed circuit where the alignment of the pallets remains constant, eliminating the need for rotating elements. Pallets are halted for processing at assembly stations, where they are aligned longitudinally with the conveying direction, enabling easy access to each workpiece for the workers. Releasing the pallet is achieved with the press of a button. In the buffering section, pallets move transversely to the conveying direction, enabling the efficient storage of numerous pallets in a compact space. Upon transfer to the customer’s dipping station, pallets are once again stopped and resume transportation when the dipping station becomes available. The customer independently installed the controls and sensors.

Click on image to enlarge

Connecting machines in the assembly process of dishwasher appliances

In the manufacturing of dishwashers, it’s essential to link various workstations in a production line. These stations operate with different cycle and changeover times, necessitating a conveyor system that can appropriately stagger and buffer dishwasher casings between them. Additionally, the conveyor system must facilitate halting casings for visual inspections using image processing and allow for manual assembly of additional components. To accommodate manual tasks, the conveyor technology should transport casings at an ergonomic height, ensuring both safe transportation and easy removal by workers. In addition, the production line requires suitable guarding for enhanced safety.

The optimal solution for this task was the implementation of the SPU 2040 accumulating pallet recirculation system. In this facility, the system was configured as a dual-line conveyor to safely transport sizable dishwasher casings (approximately 800 x 600 x 400 mm). Components are introduced into the system on pallets using a flat top chain. Upon removal of the workpieces, the empty pallets are smoothly conveyed over the tail and then transported back, suspended below the transport level. A key challenge was designing the pallets to accommodate the large dishwasher casings and navigate around the compact tail. The solution involved constructing the pallets with flexible yet interconnected mk profiles, maintaining a fixed distance. Upon reaching the start of the transport line, the pallets are conveyed back to the upper transport level, ready to accept new workpieces. This design eliminates the need for a second conveyor level or complex lift-and-lower units with intricate control elements. Furthermore, it eliminates the requirement to load the pallets onto the belt, whether through manual or automatic means. mk efficiently incorporated the necessary guarding from their extensive standard portfolio, adapting and integrating them seamlessly into the system.

Click on image to enlarge