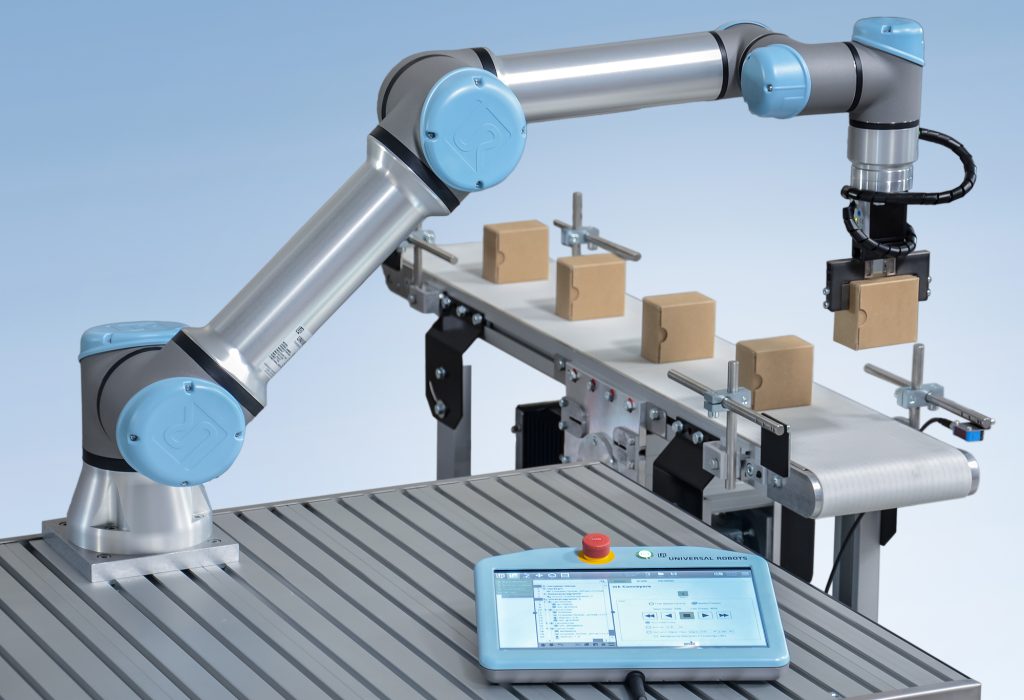

The mk Technology Group is now part of the Universal Robots partner network and provides conveyor technology which can be integrated quickly and simply into your cobot application through the URCap plug-in.

mk now provides all users of Universal Robots individual belt conveyors for simple integration in their cobot application. The convenient URCap plug-in simplifies the set-up and programming of the conveyor.

The UR+-approved belt conveyor GUF-P 2000 has a suitable version for every application. Conveyors are available in widths from 50 to 800 mm and lengths up to 10,000 mm. In addition, maximum total loads of 75 kg and speeds of up to 80 m/min are possible. As belt conveyors generally transport the goods without any special requirements in terms of their position or support geometry, they are particularly suitable for vision-supported processes. Since the belt conveyor is constructed in a modular aluminium profile construction, it has T-slots in the conveyor frame on both sides. These facilitate integration into the system as well as enabling side rails, sensors and other accessories to be attached.

The mk-Conveyors-URCap plug-and-play solution ensures fast and problem free communication between the conveyors and the cobots. It is compatible with all UR models in the e-series. Installation is simple and the intuitive user interface allows you to control up to 2 belt conveyors. The conveyor receives the commands for start/stop, direction and speed via the plug-in, but can also convey goods up to a sensor signal or for a certain period of time. The process layout remains customisable, even without programming knowledge.

As the sole UK & Ireland distributor for mk conveyors, we can help you optimise your UR cobot processes and use mk belt conveyors together with the free URCap plug-in. Get in touch to find out more!