Conveying Rails for Vehicle Seats

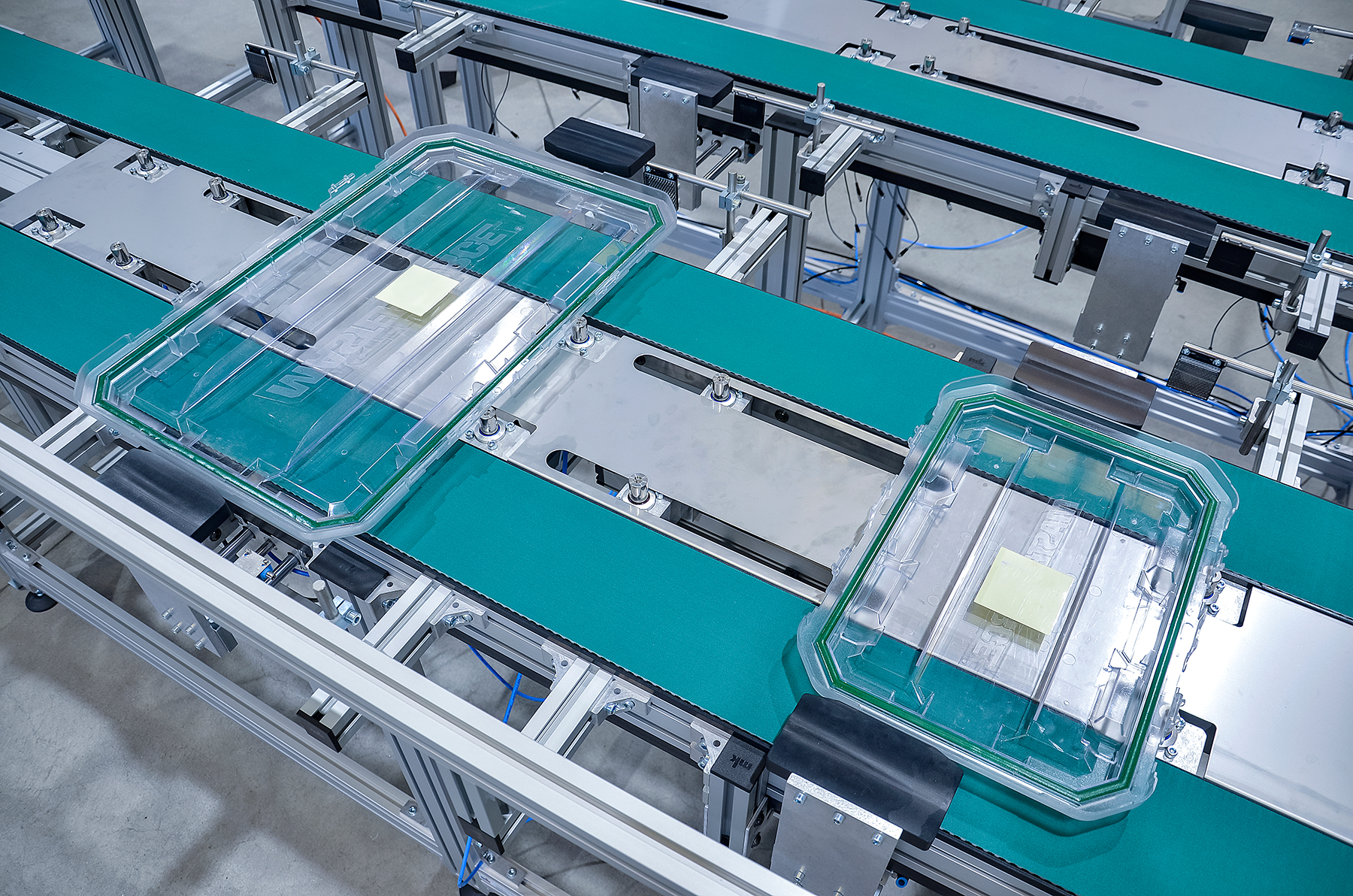

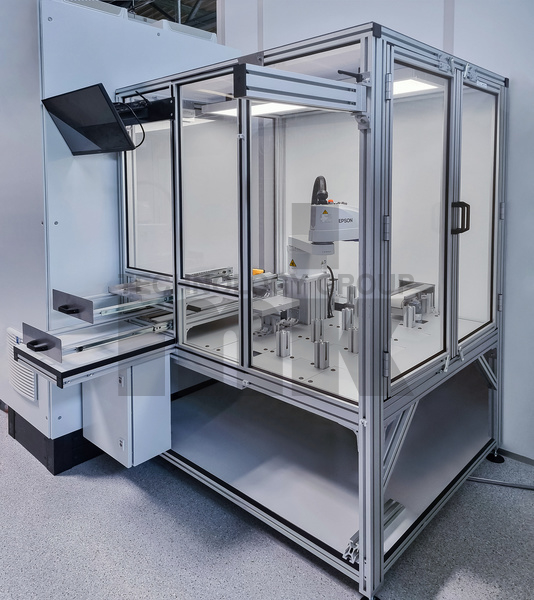

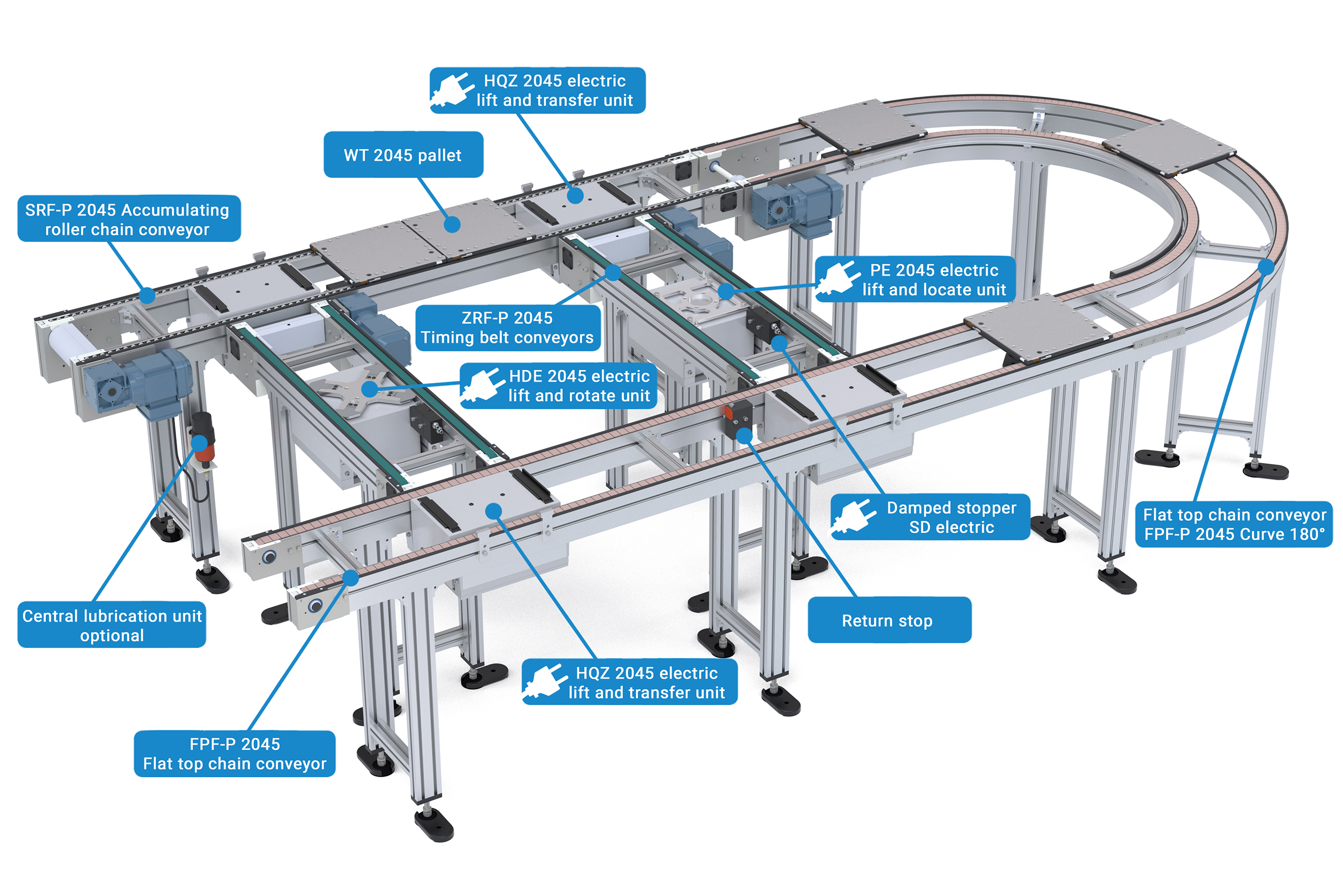

Conveying and aligning 🚗⚙️🦾 rails for vehicle seats using mk Conveyors An automotive supplier produces steel rails for the seat adjustment of vehicle seats. It is a highly automated production process therefore the automatic conveyor systems that transport the rails from one machining process to the next – for example, from punching to welding – … Read more